machining surface finish callout

Regardless both are applied after the mold cavities have been completely machined and their soon-to-be-textured surfaces smoothed to the requisite level. Two distinct processes are available but which one to use depends on the type of finish its surface depth and the mold material.

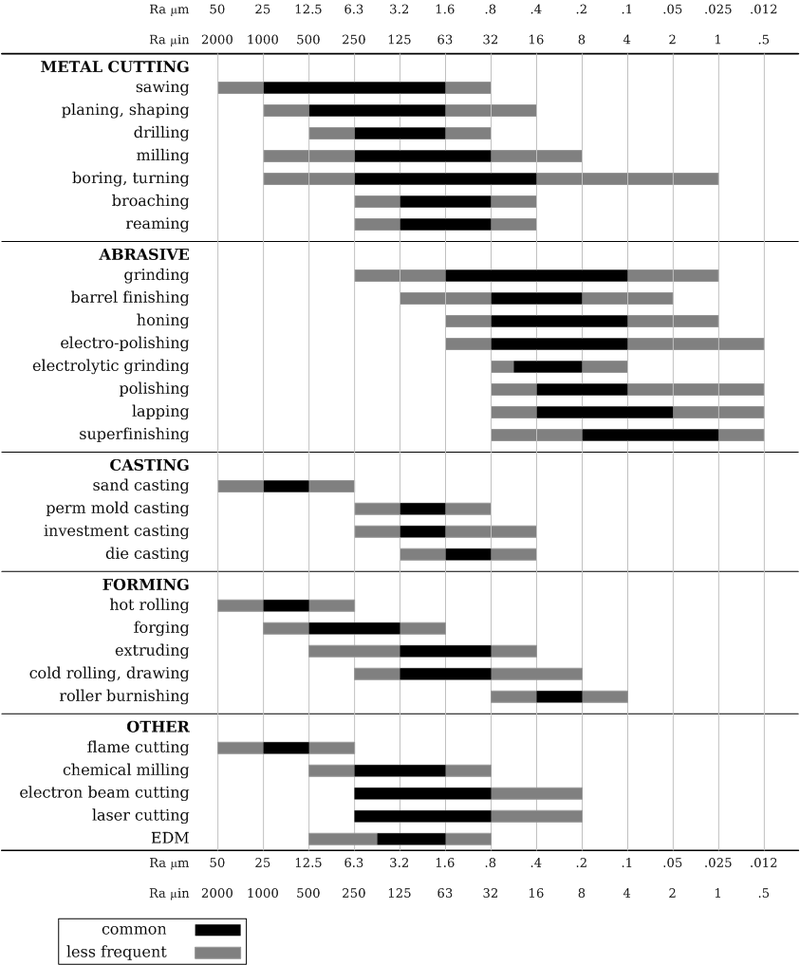

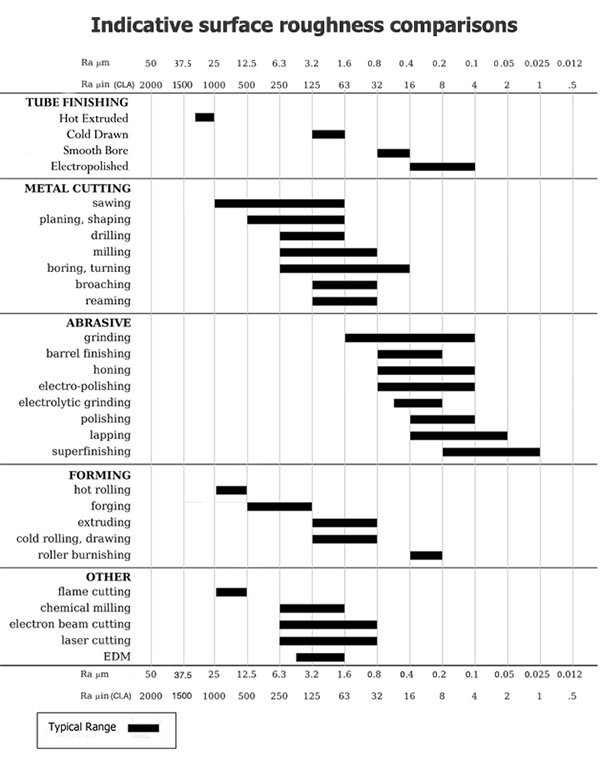

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

But is that really true.

. So how far off can the center actually be. Many who are not familiar with GDT True Position may jump to the conclusion that they just need to locate within a thou and a half 00015 on X and Y and all will be well. Lets say the callout gives a true position tolerance of 00015.

For light texturing a corrosive chemical is applied in a controlled manner etching the mold. To understand the answer we must understand how to calculate.

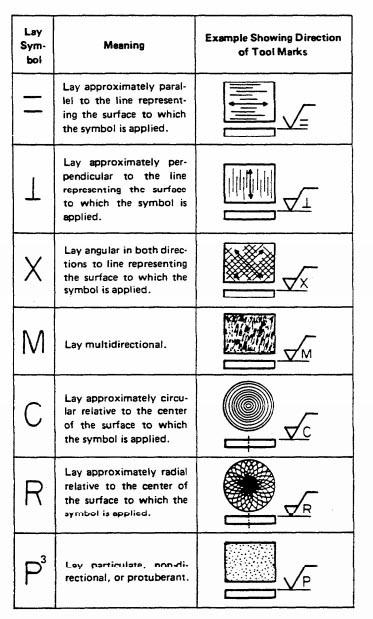

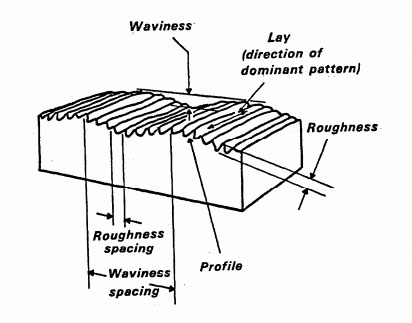

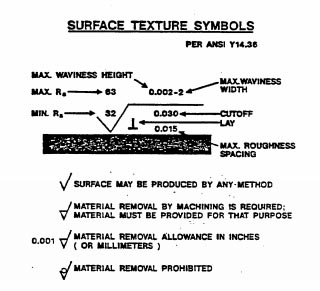

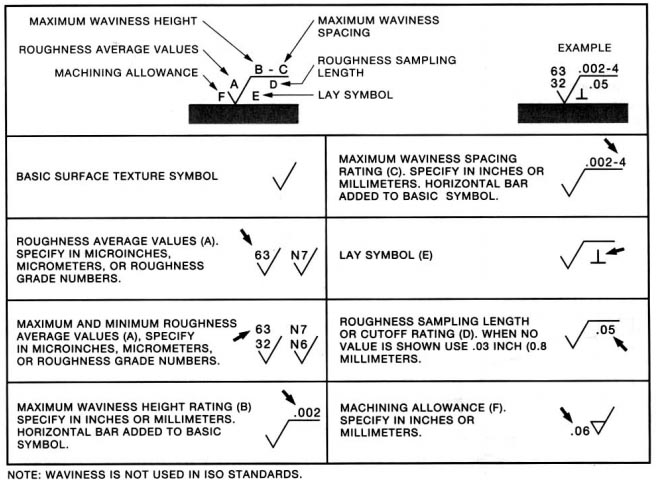

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Complete Surface Finish Chart Symbols Roughness Conversion Tables

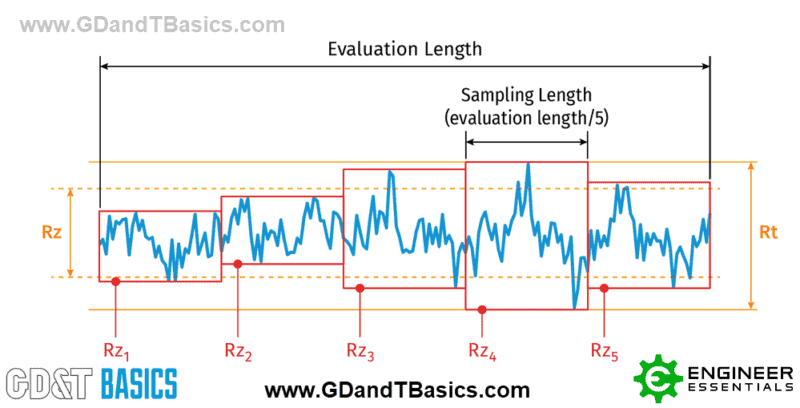

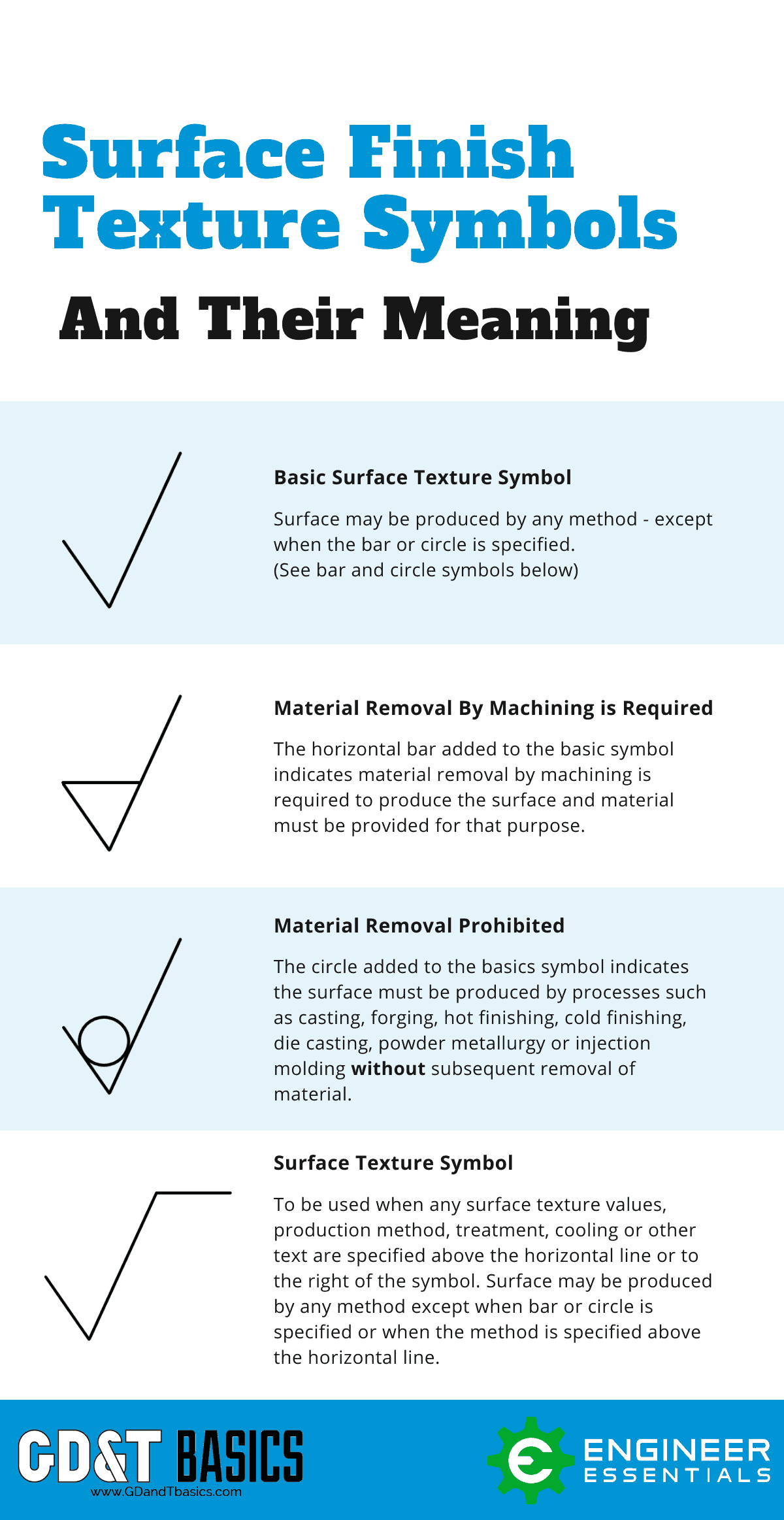

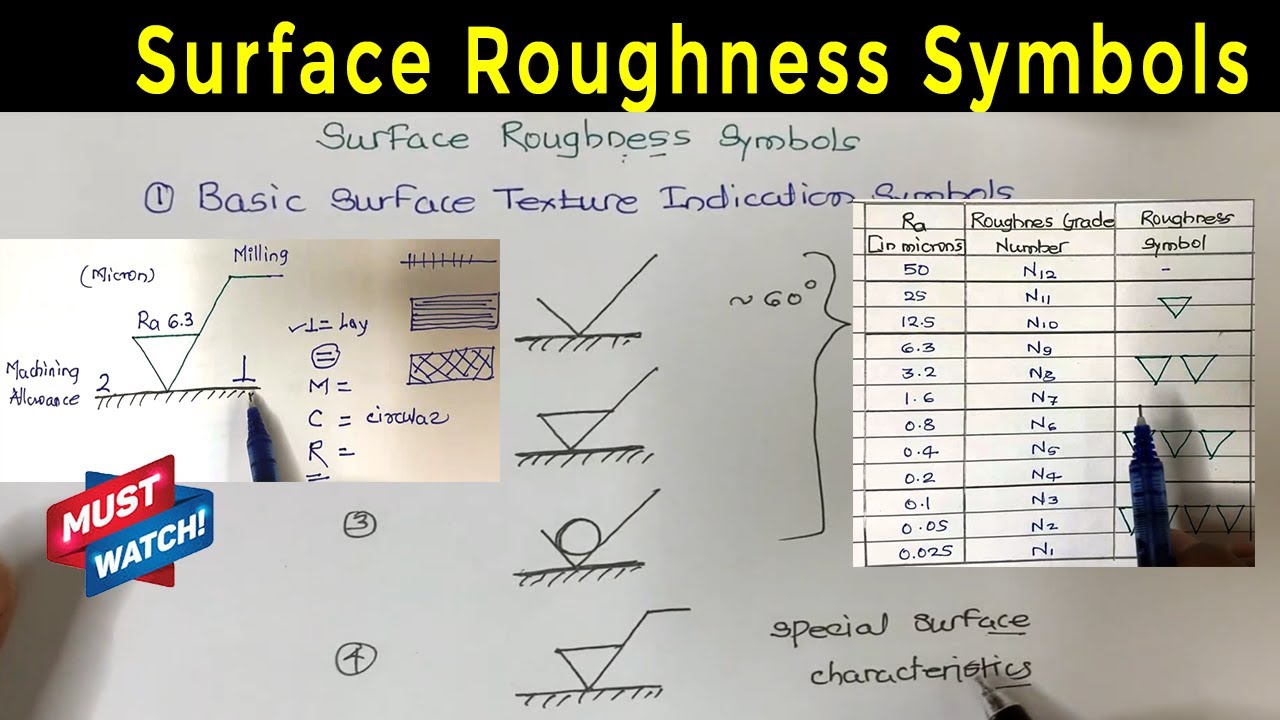

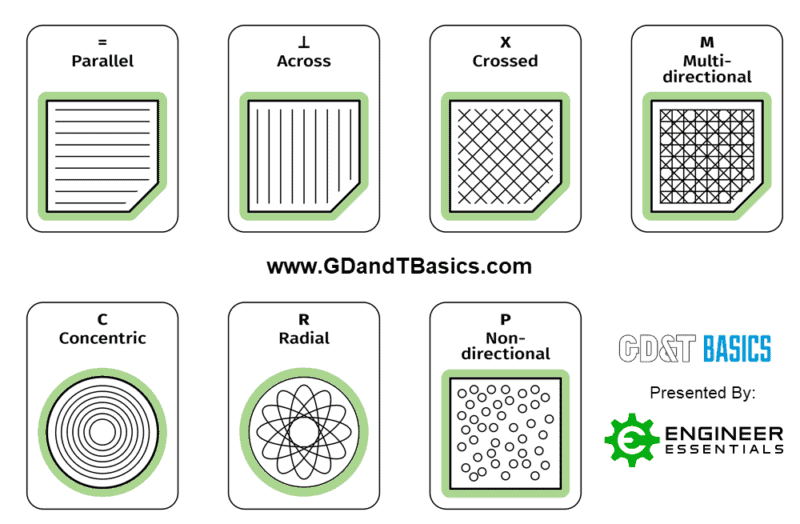

The Basics Of Surface Finish Gd T Basics

Why Use A Surface Finish Chart Metal Surface Finish

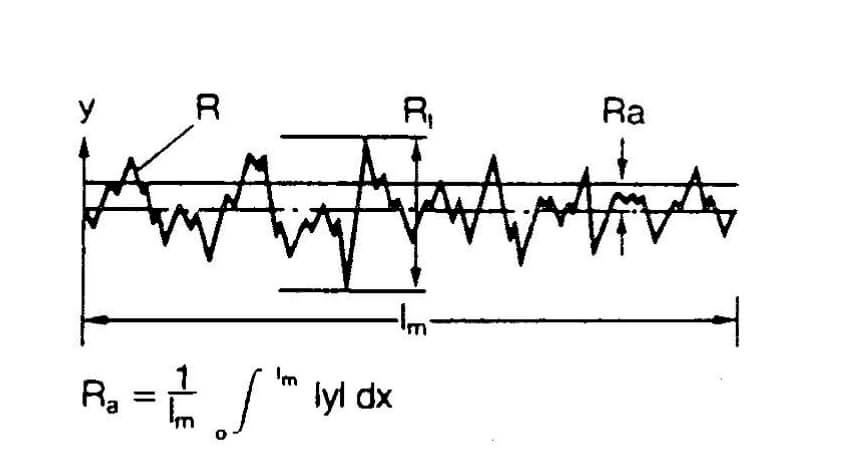

Surface Finish Quality Ra Rz Rt Surface Roughness Measuring Finish

Complete Surface Finish Chart Symbols Roughness Conversion Tables Surface Finish Symbols Surface Surface Roughness

Surface Roughness Indication To Iso Standard Autodesk Community

Complete Surface Finish Chart Symbols Roughness Conversion Tables

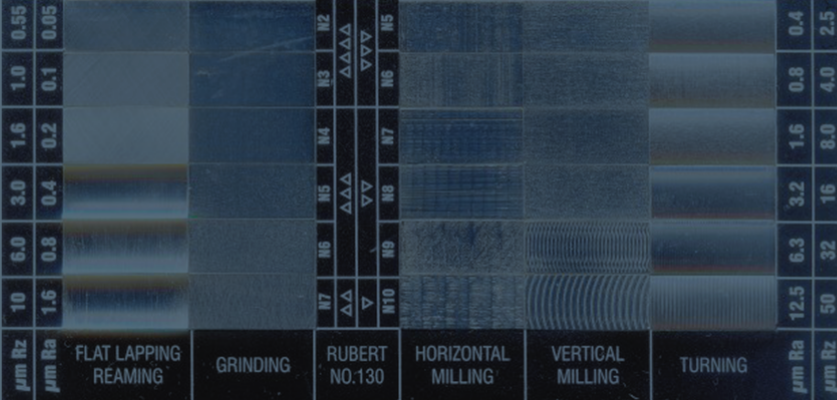

Machining Surface Finish Chart Conversion Comparator Method Degree Ra Rz Rms

The Basics Of Surface Finish Gd T Basics

The Basics Of Surface Finish Gd T Basics

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

The Basics Of Surface Finish Gd T Basics

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Solved Iso Surface Roughness Symbol Missing Roughness Autodesk Community Fusion 360